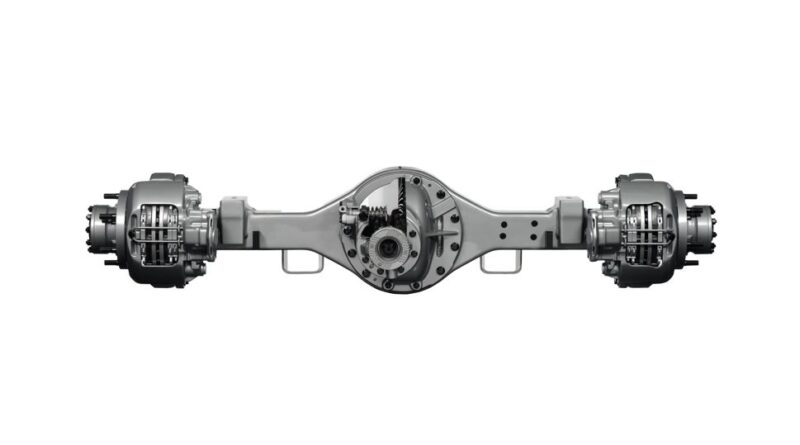

Differential Gear Box Design Pdf Gear Mechanical Engineering The differential gear is a mechanism which differentiates the power transmission ratio to the wheels. the final drive also integrated with it. Functions of differential gear box. the need of differential gearbox: differential gearbox location : principle of differential differential gearbox diagram construction of differential: major components of differential working of differential gearbox : types of differential 1) conventional type 2) non slip or self locking type 3) double.

Gear Design Pdf Gear Machines The double reduction type differential provides further speed reduction through an additional gear. this differential is commonly used in heavy duty automobiles that require larger gear reduction between the engine and wheels, enhancing torque delivery and improving performance. The differential consists of a system of gears arranged in such a way that connects the propeller shaft with the rear axles. the main objective of this paper is to perform mechanical design of differential gear box and analysis of gears in gear box. Differential gearbox introduction: differential gearbox: definition, types, components, functions, materials, principle, working process & advantages: – differential gears form a group of gears that transfer power from the engine to the wheels while enabling them to rotate at varying speeds. with back tire drive, the differential is between the rear wheels, which are associated or connected. A rear wheel drive vehicle requires a differential at the rear axle while all wheel drive vehicle requires differential gear system for each and every axle. we have designed, analysed and fabricated a single stage open differential to be used for a single seater all terrain vehicle.

Design Of Mechanical Drives And Gear Systems For Machine Tools Pdf Differential gearbox introduction: differential gearbox: definition, types, components, functions, materials, principle, working process & advantages: – differential gears form a group of gears that transfer power from the engine to the wheels while enabling them to rotate at varying speeds. with back tire drive, the differential is between the rear wheels, which are associated or connected. A rear wheel drive vehicle requires a differential at the rear axle while all wheel drive vehicle requires differential gear system for each and every axle. we have designed, analysed and fabricated a single stage open differential to be used for a single seater all terrain vehicle. Working principle of differential system and final drive differential unit is a special arrangement of gears to permit one of the rear wheels of the tractor to rotate slower or faster than the other. while turning the tractor on a curved path, the inner wheel has to travel lesser the tractor to move faster than the other at the turning point. The document summarizes the design and working of a differential gear. it describes how a differential gear allows the left and right drive wheels to rotate at different speeds while turning, transmitting power from the engine. it discusses the types of differentials including open, locking, and limited slip differentials.

Gear Design Pdf Gear Machines Working principle of differential system and final drive differential unit is a special arrangement of gears to permit one of the rear wheels of the tractor to rotate slower or faster than the other. while turning the tractor on a curved path, the inner wheel has to travel lesser the tractor to move faster than the other at the turning point. The document summarizes the design and working of a differential gear. it describes how a differential gear allows the left and right drive wheels to rotate at different speeds while turning, transmitting power from the engine. it discusses the types of differentials including open, locking, and limited slip differentials.

Machine Design Pdf Gear Machines

Machine Design Pdf Gear Steel

Differential Gear Construction And Working The Machine Design