Encoder Allen Bradley Pdf Feedback Electric Motor Each replacement kit is designed for the encoder type and version that is installed on a specific model of an hpk seriestm motor. refer to catalog number explanation on page 3 for a chart that defines the motor and encoder combinations. use this document if you are responsible for replacing the encoder on an allen bradley® hpk series motor. Quickly access technical documents to design and implement a kinetix motion solution using allen bradley bulletin 842 and 845 absolute encoders.

Encoder Pdf Electric Motor Bipolar Junction Transistor Encoder feedback is compatible with programmable controllers, numerical controllers, motion controllers, and other positioning systems. rockwell automation offers light duty and heavy duty incremental encoders for differing shaft loads. Electrical noise generated by ac power, electric motors, fluorescent lighting, relays, and many other sources can cause a plethora of problems in electrical systems. for the encoder in your system these problems can range from simple miscounting to a complete servo system lockup. Amci user manuals for products including plc based automation solutions, resolver modules, stepper motors, plc position sensing products & rotary encoders. Motor and auxiliary feedback configurations feedback connections are made at the 2 pin motor feedback (mf) connector and the 15 pin universal feedback (ufb) connector. these examples illustrate how you can use the bulletin 2198 connector kits for making these connections.

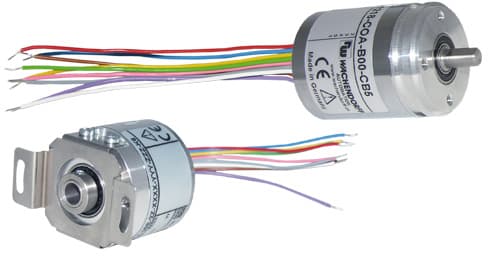

Motor Feedback Encoders Shaft Encoders Incremental Encoders Amci user manuals for products including plc based automation solutions, resolver modules, stepper motors, plc position sensing products & rotary encoders. Motor and auxiliary feedback configurations feedback connections are made at the 2 pin motor feedback (mf) connector and the 15 pin universal feedback (ufb) connector. these examples illustrate how you can use the bulletin 2198 connector kits for making these connections. Replace multiple encoders with a single 842hr encoder today’s high performance digital servo drive systems require absolute feedback for position control and high resolution incremental feedback for speed control. conventional systems use multiple incremental and absolute encoders to achieve this. the new allen bradley 842hr sine cosine encoder combines the advantages of incremental and. Only an authorized allen bradley repair center can service this item. see rockwell automation support for assistance to locate the nearest repair center. store or operate your motor in a clean and dry location within the environmental conditions that are listed in specifications on page 19.

Motor Feedback Encoders Shaft Encoders Incremental Encoders Replace multiple encoders with a single 842hr encoder today’s high performance digital servo drive systems require absolute feedback for position control and high resolution incremental feedback for speed control. conventional systems use multiple incremental and absolute encoders to achieve this. the new allen bradley 842hr sine cosine encoder combines the advantages of incremental and. Only an authorized allen bradley repair center can service this item. see rockwell automation support for assistance to locate the nearest repair center. store or operate your motor in a clean and dry location within the environmental conditions that are listed in specifications on page 19.

Encoder Motor Feedback Mda Controls