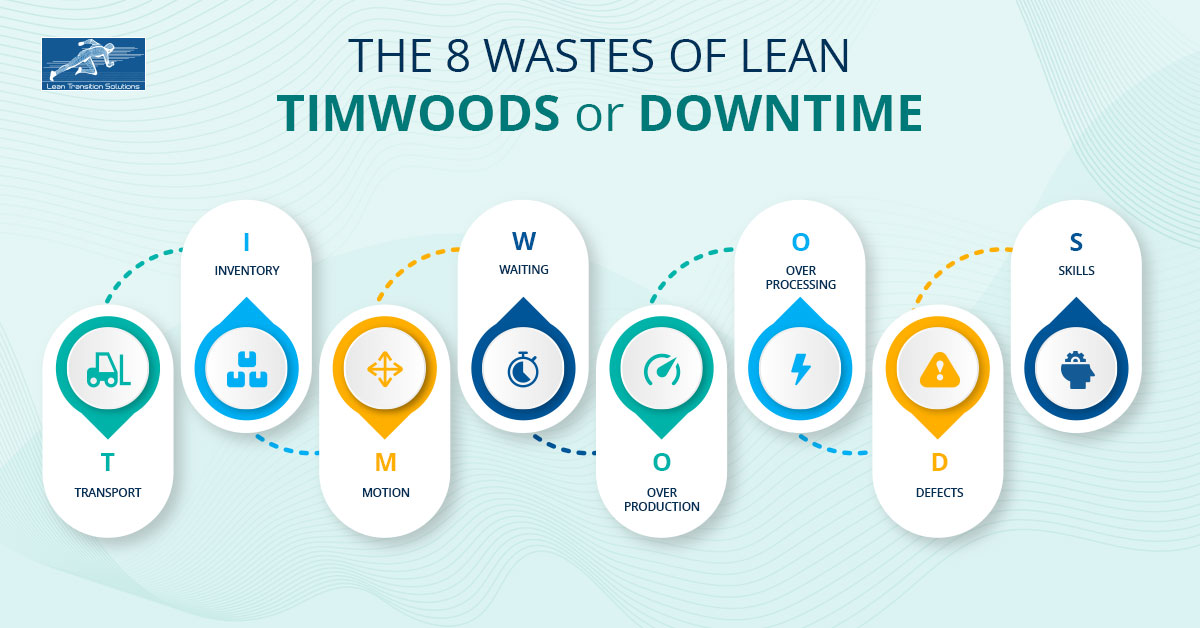

8 Waste For Lean Manufacturing Pdf Identifying and eliminating the 8 wastes the first step to reducing waste is recognizing that they exist and having an effective process for identifying them. value stream mapping (vsm) is a lean management method for analyzing the current state and designing a future state. it shows the flow of information and material as they occur. The 8 wastes of lean are defects, overprocessing, waiting, non utilized talent, transportation, inventory, motion, and excess processing.

7 Waste Dalam Lean Manufacturing Pdf What are the seven wastes of lean manufacturing or 7 mudas? muda is a non value adding process that costs you money and earns you nothing as a business. Learn how process mapping in lean manufacturing helps eliminate excess processing, one of the 8 wastes of lean, for a more efficient workflow. The most damaging waste present in the lean manufacturing is usually overproduction. it causes over stocking, extra burden of storage and concealed quality problems. Learn the definition and examples of the 7 wastes in lean manufacturing, a categorization of the major sources of waste in mass production. the 7 wastes are overproduction, waiting, conveyance, processing, inventory, motion, and correction.

8 Wastes Of Lean Manufacturing Signs Displayed The most damaging waste present in the lean manufacturing is usually overproduction. it causes over stocking, extra burden of storage and concealed quality problems. Learn the definition and examples of the 7 wastes in lean manufacturing, a categorization of the major sources of waste in mass production. the 7 wastes are overproduction, waiting, conveyance, processing, inventory, motion, and correction. Do you know the 8 wastes of lean? this handy guide will make your business more efficient in no time at all. This guide breaks down the 8 types of waste in lean manufacturing that affect your daily productivity, shows their real impact on your bottom line, and gives you practical steps to eliminate them using machine data and modern monitoring tools.

Identifying The Lean Manufacturing Waste In Your 41 Off Do you know the 8 wastes of lean? this handy guide will make your business more efficient in no time at all. This guide breaks down the 8 types of waste in lean manufacturing that affect your daily productivity, shows their real impact on your bottom line, and gives you practical steps to eliminate them using machine data and modern monitoring tools.