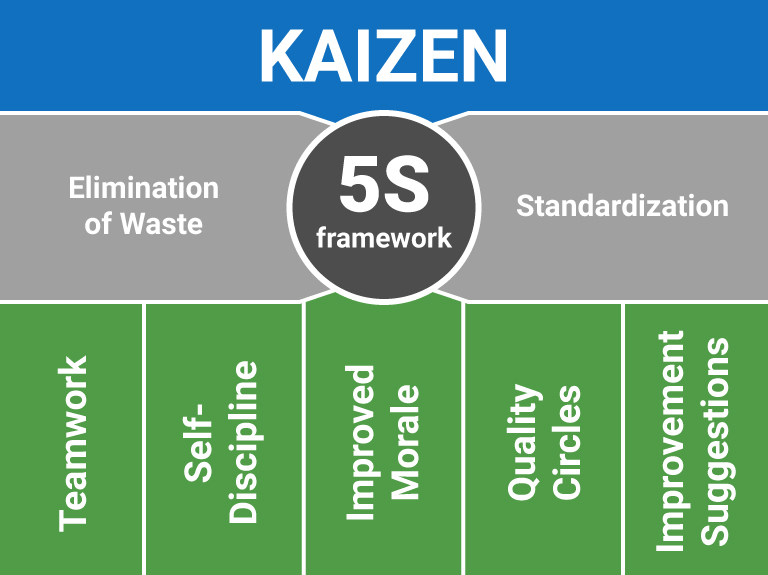

5s Implementation Kaizen Mindset Pdf Lean(kaizen 5s) dual implementation #improvement #5s#kaizen #ivd #short@ivdmanufacturing7208neeraj chopra 2023meow meow. Kaizen is a philosophy centered on the concept of continuous improvement. it advocates for ongoing efforts to enhance processes, products, or services incrementally. rooted in the japanese culture, kaizen encourages every employee, from top management to frontline workers, to contribute ideas for improvement. what is 5s? 5s is a systematic approach to workplace organization derived from.

Kaizen Through 5s Implementation Pdf Systems Science Production The 5s methodology enables a reduction in search time and facilitates access to materials and information in need, bringing various benefits:. Together, 5s and kaizen can create a culture of continuous improvement throughout the organization. how continuous improvement aligns with organization continuous improvement is the process of making small, incremental changes to improve processes and products over time. Another part of 5s when you have a 5s kaizen environment you organize the work space efficiently, store items effectively, maintain the work area well, and sustain the system and standardize it. in addition, you add another element which is safety. you now establish an environment for optimal continuous improvement. Implementation of 5s and kaizen has large horizontal development and they can be implemented in all the workstations of the organisation.

Lean Kaizen 5s Dual Implementation Improvement 5s Kaizen Ivd Another part of 5s when you have a 5s kaizen environment you organize the work space efficiently, store items effectively, maintain the work area well, and sustain the system and standardize it. in addition, you add another element which is safety. you now establish an environment for optimal continuous improvement. Implementation of 5s and kaizen has large horizontal development and they can be implemented in all the workstations of the organisation. 5s is the foundation of all improvements and is the key component of establishing a visual workplace. both are a part of kaizen — a system of continual improvement which is a component of lean manufacturing. a 5s program focuses on having visual order, organisation, cleanliness and standardisation. the results you can expect from a 5s program are: improved profitability, efficiency, service. Strengths of 5s as an initial improvement activity include the following: • successful implementation of 5s requires that processes be defined and process ownership assigned. this begins to create basic process team structures with assigned responsibility and accountability for process conditions and performance.

Lean Applied At Workplace 5s Implementation Lean Motivation Subscribe 5s is the foundation of all improvements and is the key component of establishing a visual workplace. both are a part of kaizen — a system of continual improvement which is a component of lean manufacturing. a 5s program focuses on having visual order, organisation, cleanliness and standardisation. the results you can expect from a 5s program are: improved profitability, efficiency, service. Strengths of 5s as an initial improvement activity include the following: • successful implementation of 5s requires that processes be defined and process ownership assigned. this begins to create basic process team structures with assigned responsibility and accountability for process conditions and performance.

What Is Kaizen Continuous Improvement 60 Off

Three Lean Tools To Nurture Continuous Improvement Kaizen Kaikaku