Selective Laser Sintering Sls Unit 3 Pdf Selective laser sintering is an additive rapid prototyping technique that uses a high power laser to fuse small particles of thermoplastic, metal, polyamide (nylon), ceramic, or glass filled nylon. sls offers the key advantage of making functional parts in essentially final materials, depending on use of the part. brian reniker selective laser sintering sls prototypes like many rapid. The document provides an overview of selective laser sintering (sls), including its introduction, advantages, limitations, applications, and two case studies. sls is a rapid prototyping technique that utilizes powdered materials to create complex designs efficiently and with a good surface finish, but it also has high equipment costs and requires skilled labor. the case studies highlight the.

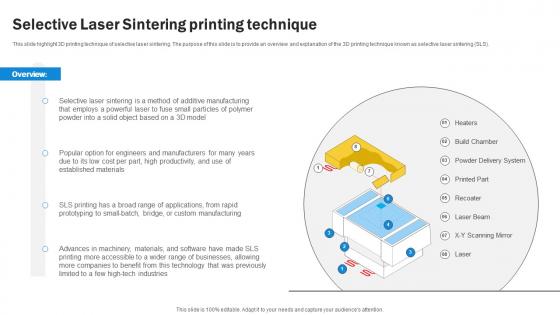

Selective Laser Sintering Sls Presentation Free To Download 10 how sls (selective laser sintering) process works (cont) click here to view a diagram on how the selective laser sintering process works. 11 sls uses produces patterns for casting. creating highly detailed functional parts. rapid tooling from powdered carbon steel. significant impact on prototype manufacturing industry and rp job shops. Selective laser sintering free download as powerpoint presentation (.ppt .pptx), pdf file (.pdf), text file (.txt) or view presentation slides online. this document provides an overview of selective laser sintering (sls), a type of 3d printing. sls uses a high power laser to fuse powdered material layer by layer, allowing complex objects to be produced quickly. it discusses the sls process. Selective laser sintering (sls) manufacturing technique made with plastic elastomer powder sample built layer by layer horizontal slide with fixed vertical movement powder stays on table filetype ‘.stl’ used structural triangle language finished sample cools for 12 24 hrs then pulled out of powder sls machine sls powder sls con’t powder nylon 11 for high strength and elasticity nylon. Classification of sls kruth, jp, et al., binding mechanisms in selective laser sintering and selective laser melting, rapid prototyping journal, (2005). classification of sls liquid phase sintering no distinct binder and structural material rather than the distinction between binder and structural materials, there is a distinction between.

Selective Laser Sintering Presentation Free To Download Selective laser sintering (sls) manufacturing technique made with plastic elastomer powder sample built layer by layer horizontal slide with fixed vertical movement powder stays on table filetype ‘.stl’ used structural triangle language finished sample cools for 12 24 hrs then pulled out of powder sls machine sls powder sls con’t powder nylon 11 for high strength and elasticity nylon. Classification of sls kruth, jp, et al., binding mechanisms in selective laser sintering and selective laser melting, rapid prototyping journal, (2005). classification of sls liquid phase sintering no distinct binder and structural material rather than the distinction between binder and structural materials, there is a distinction between. Sls selective laser sintering. rapid prototyping carnegie mellon andy sadhwani. selective laser sintering (sls). manufacturing technique made with plastic elastomer powder sample built layer by layer horizontal slide with fixed vertical movement powder stays on table. This document provides an overview of selective laser sintering (sls), a 3d printing technique that uses a laser to fuse powdered material together layer by layer. it defines sls, describes the basic multi step process, and lists common input parameters and materials used. the document outlines key advantages like lack of support structures and fast printing, as well as limitations such as.

Selective Laser Sintering Powerpoint Presentation And Slides Ppt Sls selective laser sintering. rapid prototyping carnegie mellon andy sadhwani. selective laser sintering (sls). manufacturing technique made with plastic elastomer powder sample built layer by layer horizontal slide with fixed vertical movement powder stays on table. This document provides an overview of selective laser sintering (sls), a 3d printing technique that uses a laser to fuse powdered material together layer by layer. it defines sls, describes the basic multi step process, and lists common input parameters and materials used. the document outlines key advantages like lack of support structures and fast printing, as well as limitations such as.

Selective Laser Sintering Sls Diagram Diagram Quizlet