Hydrated Lime Processing Handling Dosing Lime Systems Hydrated lime quicklime can be processed into hydrated lime by crushing the quicklime, adding water to the crushed lime (water accounts for approximately 1% of raw hydrate), and then classifying the hydrated lime to ensure it meets customer specifications before it is transported. About 15 percent of all lime produced is converted hydrators: atmospheric and pressure. atmospheric continuous mode to produce high calcium and dolomitic produce only a completely hydrated dolomitic lime or wet scrubbers perform the hydrating process and may be milled and then conveyed to air separators.

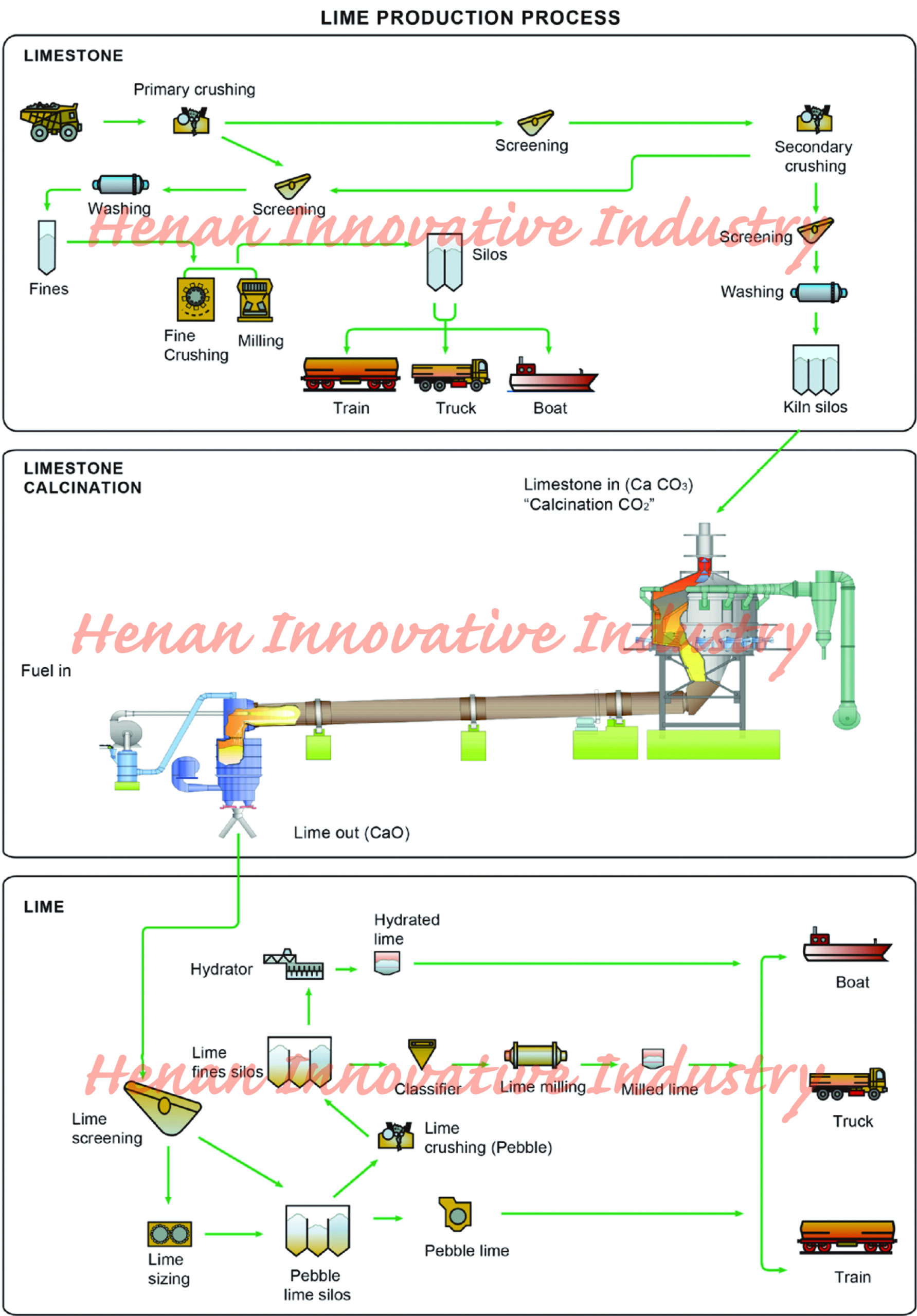

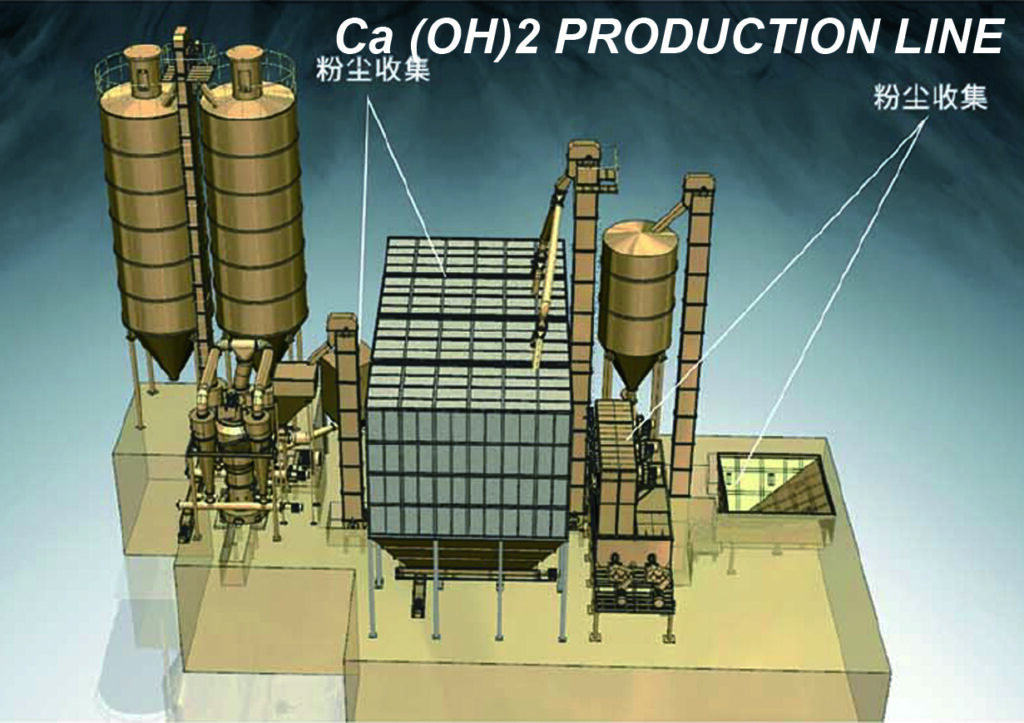

Hydrated Lime Production Line Henan Innovative Industry The process flow of hydrated lime production line mainly includes raw material storage and transportation, limestone calcination, finished product transportation and flue gas treatment. Hydrated lime, also known as calcium hydroxide, is a versatile compound widely used in various industries. with applications spanning construction, agriculture, water treatment, and more, hydrated lime has become an essential material due to its unique properties. this blog will delve into the production process, properties, and diverse uses of hydrated lime and hydrated lime powder, along. The production of calcium hydroxide is a very complex chemical reaction process, in which the precise control of water is particularly important. here is a technical engineer from cronus to explain how to make hydrated lime. hydrated lime, also known as calcium hydroxide (ca (oh)₂), is an important inorganic compound with a wide range of applications in various industries, including. When the hydrated lime is produced, the carefully controlled process of hydration enables the balance between the water and the calcium oxide to be such that the hydrated lime is produced as a dry powder when it exits the hydration bath.

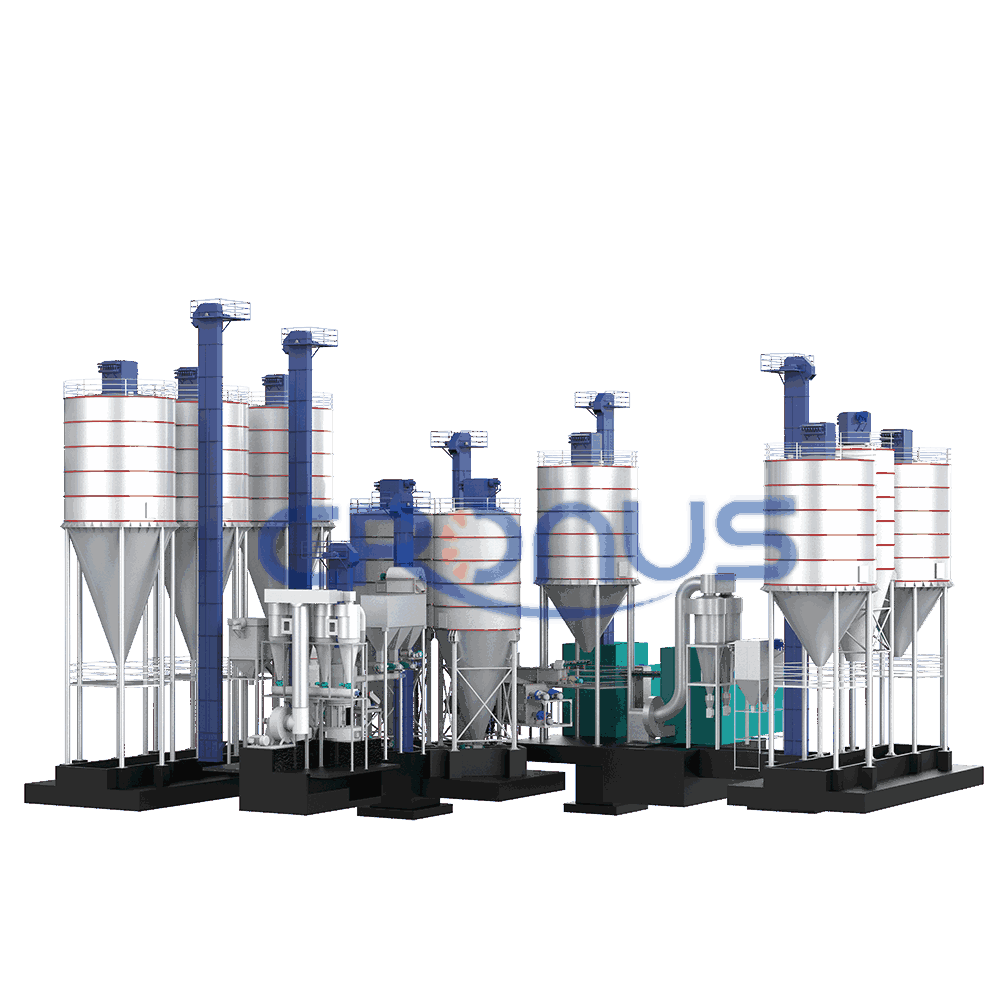

Hydrated Lime Production Line Henan Innovative Industry The production of calcium hydroxide is a very complex chemical reaction process, in which the precise control of water is particularly important. here is a technical engineer from cronus to explain how to make hydrated lime. hydrated lime, also known as calcium hydroxide (ca (oh)₂), is an important inorganic compound with a wide range of applications in various industries, including. When the hydrated lime is produced, the carefully controlled process of hydration enables the balance between the water and the calcium oxide to be such that the hydrated lime is produced as a dry powder when it exits the hydration bath. Hydrated lime is a type of dry powder made from limestone. it is created by adding water to quicklime in order to turn oxides into hydroxides. combined with water and sand or cement, hydrated lime is most often used to make mortars and plasters. its chemical name is calcium hydroxide, or ca (oh) 2. Slaked lime (ca (oh)2): also known as hydrated lime, this is the final product used for construction, water treatment, and other applications. dolomitic lime: this type of lime is produced from limestone containing magnesium carbonate and is used in the production of cement and concrete.

Hydrated Lime Production Line To Product Calcium Hydroxide Hydrated Hydrated lime is a type of dry powder made from limestone. it is created by adding water to quicklime in order to turn oxides into hydroxides. combined with water and sand or cement, hydrated lime is most often used to make mortars and plasters. its chemical name is calcium hydroxide, or ca (oh) 2. Slaked lime (ca (oh)2): also known as hydrated lime, this is the final product used for construction, water treatment, and other applications. dolomitic lime: this type of lime is produced from limestone containing magnesium carbonate and is used in the production of cement and concrete.

Process Flow Of Hydrated Lime Production Line Tb Pads

Process Flow Of Hydrated Lime Production Line Tb Pads