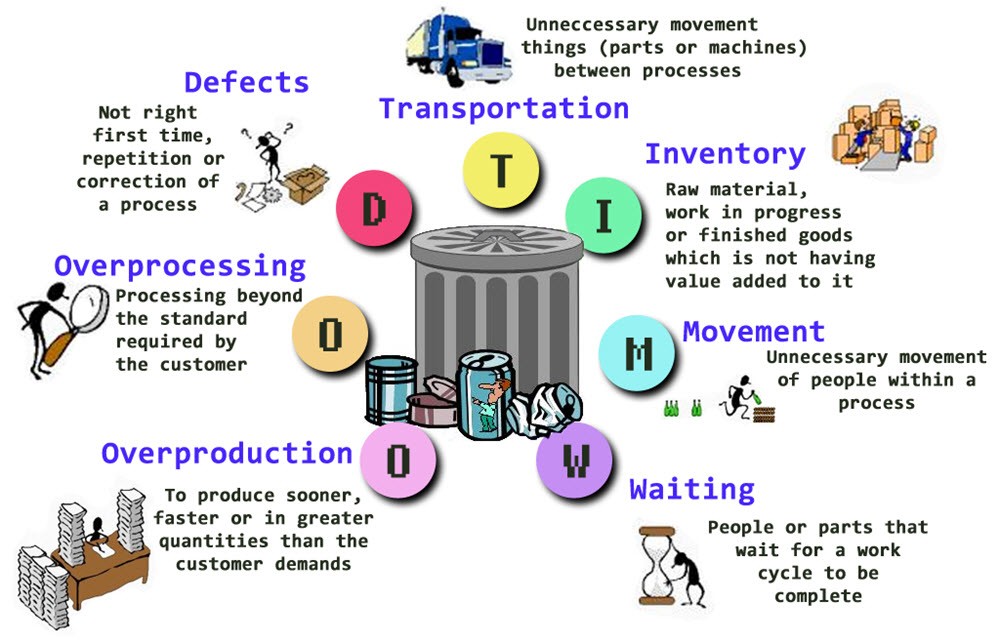

Lean And Waste Management 7 Wastes Of Lean Manufacturing 7 wastes the 7 wastes are taiichi ohno’s categorization of the seven major wastes typically found in mass production: overproduction: producing ahead of what’s actually needed by the next process or customer. the worst form of waste because it contributes to the other six. What are the seven wastes of lean manufacturing or 7 mudas? muda is a non value adding process that costs you money and earns you nothing as a business.

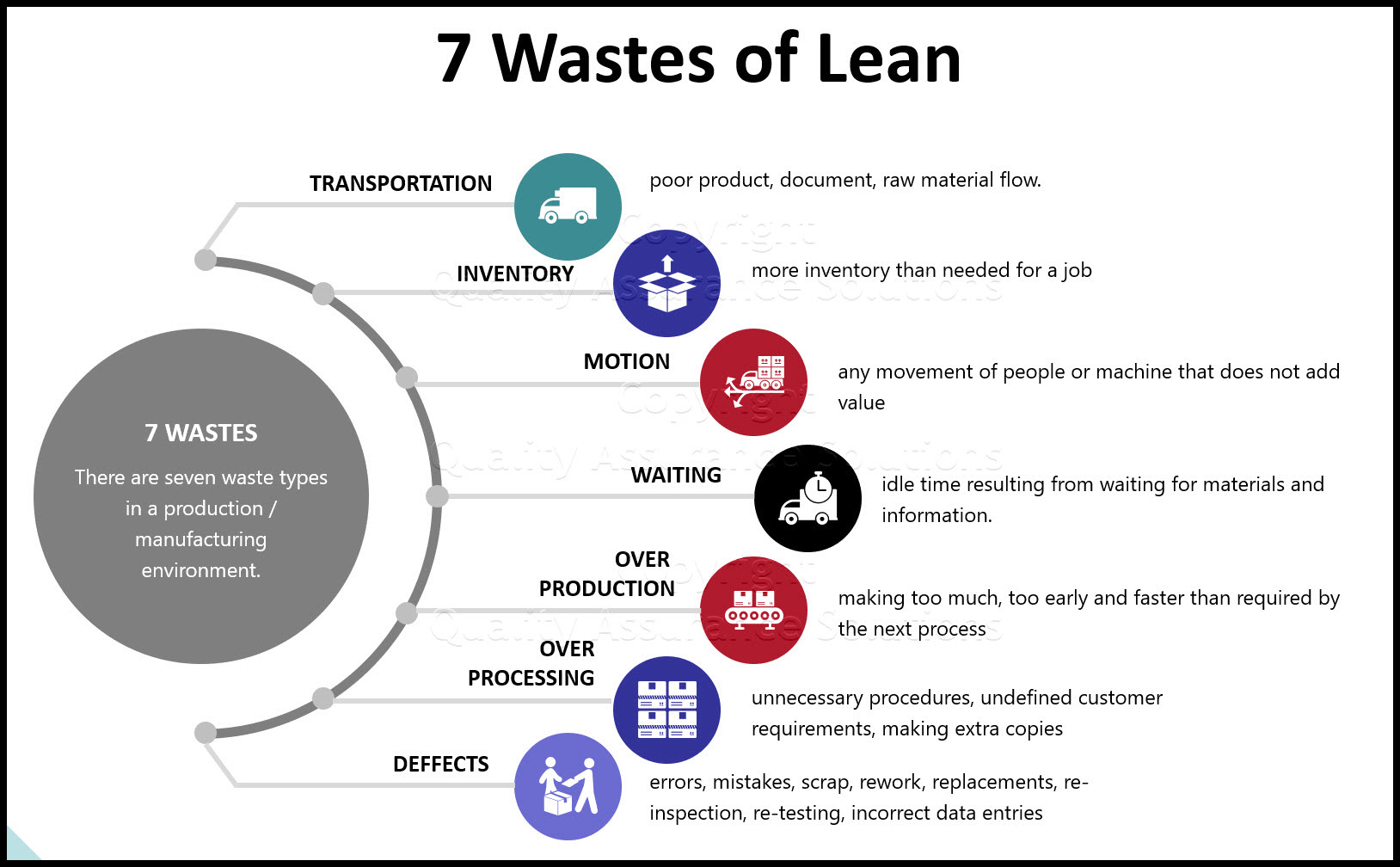

7 Wastes Lean Manufacturing Learn the 7 lean waste types—transportation, inventory, motion, waiting, overproduction, over processing, and defects. discover how to identify, categorize, and eliminate muda for better efficiency and continuous improvement. Identifying and eliminating the 8 wastes the first step to reducing waste is recognizing that they exist and having an effective process for identifying them. value stream mapping (vsm) is a lean management method for analyzing the current state and designing a future state. it shows the flow of information and material as they occur. This post explains the 7 wastes categorized by lean manufacturing that affect the quality, production time and cost of organizations. The 7 wastes of lean manufacturing relate to any activity that consumes resources but creates no value for the customer.

7 Wastes Lean Manufacturing Vrogue Co This post explains the 7 wastes categorized by lean manufacturing that affect the quality, production time and cost of organizations. The 7 wastes of lean manufacturing relate to any activity that consumes resources but creates no value for the customer. Discover the 7 wastes of lean and learn practical strategies to eliminate them, improve efficiency, and enhance customer satisfaction in your organization. An industry examples of the wastes of lean the 7 wastes of lean are descriptive and not necessarily an actionable activity. however, some organizations have used the 7 wastes of lean as a template to audit their organizational processes to provide a framework for improvement.

Seven Wastes Mudas Of Lean Manufacturing 57 Off Discover the 7 wastes of lean and learn practical strategies to eliminate them, improve efficiency, and enhance customer satisfaction in your organization. An industry examples of the wastes of lean the 7 wastes of lean are descriptive and not necessarily an actionable activity. however, some organizations have used the 7 wastes of lean as a template to audit their organizational processes to provide a framework for improvement.

The 7 Lean Wastes How To Identify And Optimize Your Workflow