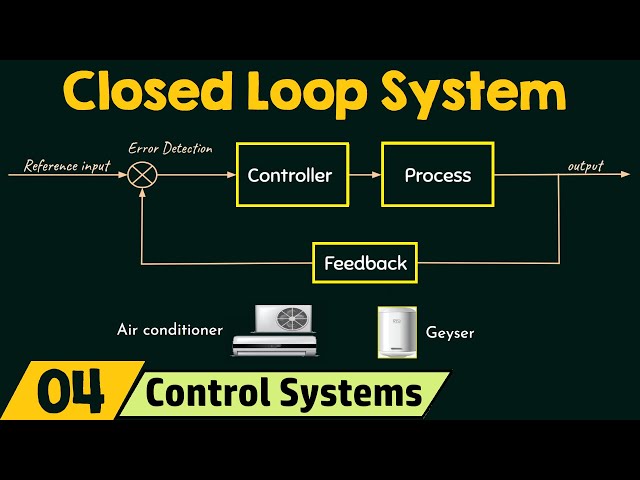

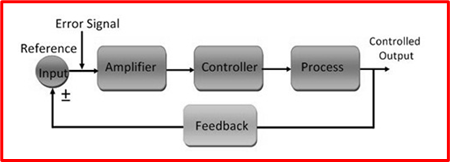

What Is Closed Loop Control Systems Ai Basics Ai Online Course In this article, we're going to discuss about closed loop control system. a closed loop control system is an electronic device that automatically regulates a system to maintain a desired state or set point without human interaction. the advantages of closed loop control systems lie in their ability to provide precision, stability, and resilience, making them indispensable in numerous. Closed loop systems closed loop systems use feedback where a portion of the output signal is fed back to the input to reduce errors and improve stability the ability of a feedback system to modify the natural dynamics of a system, and in particular to stabilise it is the basic architecture of any closed loop system.

Closed Loop Control System Basics The Industrial Steam Valve And This illustrates another type of control, known as feedforward or open loop control, where the input to the system does not depend on the output. as this example illustrates, feedforward control is not robust to disturbances { if the stick is not perfectly balanced to start, or if our hand moves very slightly, the stick will fall. Here, a feedback loop is an element of the output signal. the concept of feedback is very essential in any control system to get the output stability. control systems are classified into two types based on the connection of feedback namely closed loop control system and open loop control system. Control systems are classified by the control action which is the quantity responsible for activating the control system to produce the output. the two general classifications are open loop and closed loop control systems. Key learnings: control system definition: a control system is a set of devices that directs and manages the behavior of other systems to achieve specific results through regulation and control. open loop examples: in open loop control systems, operations such as using a manual light switch or setting a timer on a bread toaster are performed without considering the output’s effect on the.

Control Systems Open Loop Vs Closed Loop Pocket Sparky Control systems are classified by the control action which is the quantity responsible for activating the control system to produce the output. the two general classifications are open loop and closed loop control systems. Key learnings: control system definition: a control system is a set of devices that directs and manages the behavior of other systems to achieve specific results through regulation and control. open loop examples: in open loop control systems, operations such as using a manual light switch or setting a timer on a bread toaster are performed without considering the output’s effect on the. Hence, the closed loop control systems are also called the automatic control systems. traffic lights control system having sensor at the input is an example of a closed loop control system. the differences between the open loop and the closed loop control systems are mentioned in the following table. The terms automation, closed loop control and open loop control are frequently used synonymously, although there are consider able differences between them. closed loop control is a subset of automation. closed loop tasks are encountered in numerous situations in daily life. the object is to cause the status of a system to approach that of a predefined value. in control technology [5] this.

Closed Loop Control Systems Hence, the closed loop control systems are also called the automatic control systems. traffic lights control system having sensor at the input is an example of a closed loop control system. the differences between the open loop and the closed loop control systems are mentioned in the following table. The terms automation, closed loop control and open loop control are frequently used synonymously, although there are consider able differences between them. closed loop control is a subset of automation. closed loop tasks are encountered in numerous situations in daily life. the object is to cause the status of a system to approach that of a predefined value. in control technology [5] this.