Uncertainty Of Runout Measurement Abstract. this paper describes an uncertainty evaluation for the measurement of radial runout, axial runout and coning for axi symmetric measurement machine. an industrial axi symmetric measurement machine was used which consisted of a rotary table and a number of contact measurement probes located on slideways. The evaluation of measurement data guide to the expression of uncertainty in measurement (usually referred to as the gum) provides general rules for evaluating and expressing uncertainty in measurement. when a measurand, y, is calculated from.

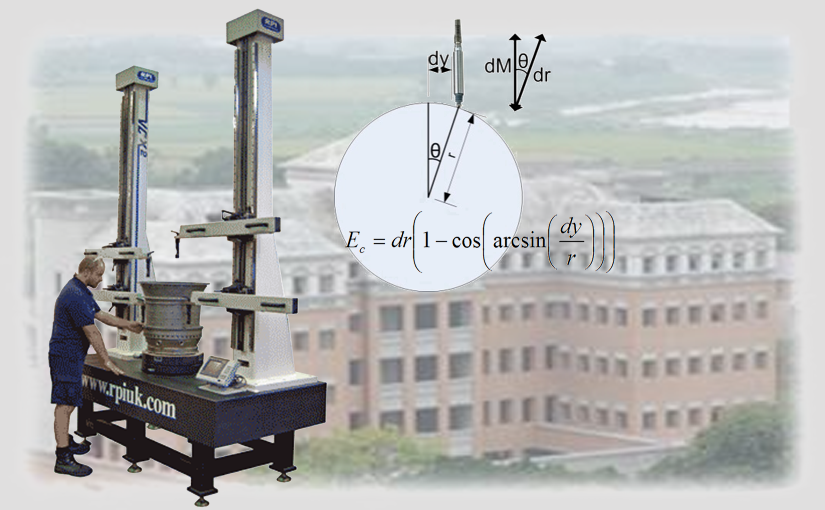

Runout Measurement By Pinpoint Laser Systems For type b2 uncertainties due to systematic effects of the runout mea suring device, the rectangular distribution is assumed with in nite fi degrees of freedom owing to the fact that a single measurement is used. It turns out that if one ignores slight changes in the measurement uncertainty associated with the angular position and assumes for further calculations the greatest uncertainty of measurement of point straight line distance the measurement uncertainty of the runout deviation is 2 times greater than the uncertainty of measurement of point. This paper describes a method of uncertainty evaluation for axi symmetric measurement machines which is compliant with gum and puma methodologies. specialized measuring machines for the inspection of axisymmetric components enable the measurement of properties such as roundness (radial runout), axial runout and coning. The approval of a series uncertainty and b series uncertainty were done as well as range control chart in statistic control,which got the same result in the approval of gear precision.by applying image measurement, various gear ring radial runout can be measured.

Circular Runout Measurement 1 Pdf This paper describes a method of uncertainty evaluation for axi symmetric measurement machines which is compliant with gum and puma methodologies. specialized measuring machines for the inspection of axisymmetric components enable the measurement of properties such as roundness (radial runout), axial runout and coning. The approval of a series uncertainty and b series uncertainty were done as well as range control chart in statistic control,which got the same result in the approval of gear precision.by applying image measurement, various gear ring radial runout can be measured. Four space diagonals. parallel to x, y, and z axes. comprehensive overall test of cmm structure, probe system, and repeatability. each measurement is a single point to single point distance which thoroughly tests the cmm. The practical use of mcm it has proven to be a fundamental tool, being able to address more complex measurement problems that were limited by the gum approximations. index terms—circular runout error, guide to the expression of uncertainty in measurement (gum), monte carlo method (mcm), measurement uncertainty.

Uncertainty Budget For The Measurement Of Radial Runout Using A Plunger Four space diagonals. parallel to x, y, and z axes. comprehensive overall test of cmm structure, probe system, and repeatability. each measurement is a single point to single point distance which thoroughly tests the cmm. The practical use of mcm it has proven to be a fundamental tool, being able to address more complex measurement problems that were limited by the gum approximations. index terms—circular runout error, guide to the expression of uncertainty in measurement (gum), monte carlo method (mcm), measurement uncertainty.